Upgrade Your Mezzanine Flooring While Avoiding Timely and Costly Replacement

MAY 1 2025 | MATERIAL HANDLING, ROBOTICS

Repair and Repurpose your Mezzanine Floors

Floors in warehouses and distribution centers often wear out over time. Mezzanine floors, pick module floors, and platform floors are especially prone to damage. Heavy equipment, pallet jacks, and foot traffic can cause gouges, slips, and uneven surfaces. These problems can make operations less safe and less efficient. If you need a solution to replace, repurpose, or resurface these floors, ResinDek® ReShield™ is the answer. This overlay flooring panel is durable, easy to install, and designed for modern industrial spaces.

Resurface Mezzanine Floors for Better Performance

Mezzanine floors are important in many facilities. They provide extra space for storage or work without taking up more ground space. However, they often face heavy use from equipment and people. Over time, this can cause the floor to wear down. Fixing these issues usually means replacing the entire floor, which is expensive and time-consuming. Instead of replacing the entire floor, resurface it with ResinDek ReShield overlay flooring panels.

ResinDek ReShield panels are strong enough to handle heavy loads. They support pallet jack rolling loads up to 3,500 pounds and (AMR) mobile robot and product loads up to 3,000 pounds.

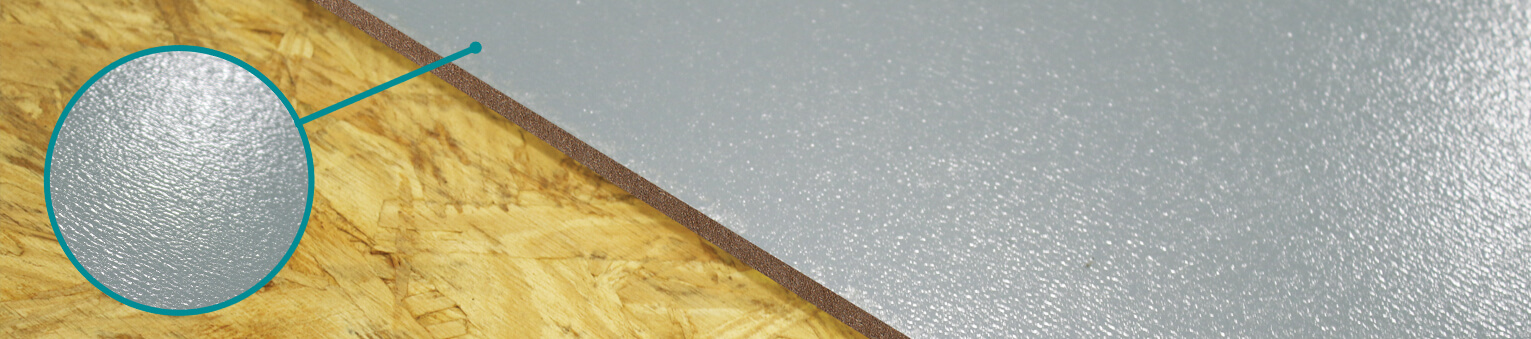

The panels are lightweight and only 1/4-inch thick. This makes them easy to install directly over existing floors like plywood, OSB, chipboard, and more. Avoid having to tear out flooring or having to spend a lot of time preparing the flooring surface for repairs. Safety is also improved with ResinDek ReShield overlay flooring panels. ResinDek ReShield panels have improved gouge and slip resistance, helping to prevent accidents in busy areas, making them a great choice for mezzanines that see a lot of traffic.

Repurpose Pick Module Floors with ResinDek® ReShield™ Overlay Flooring Panels

Pick module floors are used in warehouses to organize products for picking and packing. These floors are often under constant use by workers and equipment. Over time, they can become damaged or worn out. As operations change, you may also need to repurpose these floors for new tasks or heavier loads. ResinDek ReShield panels make this an easy task without starting from scratch.

The panels are strong enough to handle heavy equipment yet lightweight enough for an easy installation. You can install them directly over worn-out pick module floors without tearing out the old surface, saving time and money while giving the floor a new life.

ResinDek ReShield panels are also environmentally friendly. The panels are made from recycled wood fibers and formaldehyde-free resins, which makes them safe for workers and good for the planet. If your facility values sustainability, this product is a great choice for upgrading your pick module floors.

Retrofit Platform Floors for Robotics

Robotics like Autonomous Mobile Robots (AMRs) and Automated Guided Vehicles (AGVs) are becoming more common in warehouses and factories. These machines help move products quickly and efficiently, but they require strong and durable floors to operate correctly. Many existing platform floors are not built to handle robotic traffic or their specific load requirements. ResinDek ReShield panels are designed to retrofit platform floors for robotics applications.

ResinDek ReShield panels support AMR rolling loads up to 3,000 pounds, making it perfect for facilities that use robots for material handling tasks. The panels also have specialized wear resistance that stands up to robotic traffic over time without losing quality.

Retrofitting your platform floors with ResinDek ReShield is a smart way to prepare your facility for the future of robotics in industrial applications. No need to replace the entire floor—simply install ResinDek ReShield panels over your existing surface for a durable upgrade.

Why Choose ResinDek® ReShield™ Overlay Flooring Panels?

ResinDek ReShield panels offer operations professionals a simple way to fix flooring problems without major disruptions or high costs. Whether you need to resurface mezzanine floors, repurpose pick module floors, or retrofit platform floors for AMRs, this product delivers reliable results.

Here's why ResinDek ReShield panels stand out:

- Easy Installation: Lightweight panels install directly over most existing substrates without demolition or extensive preparation work.

- Durable Design: Supports heavy loads from pallet jacks and robotics (AMRs) while improving gouge and slip resistance.

- Eco-Friendly Materials: Made from recycled wood fibers with no formaldehyde.

- Versatile Applications: Works on mezzanines, pick module floors, platform floors, and more.

If your facility needs a flooring upgrade that saves time and money while improving safety and performance, ResinDek ReShield overlay flooring panels are the solution you’ve been looking for!

ADDITIONAL BLOG POSTS

MAY

1

2025

MATERIAL HANDLING, ROBOTICS

Upgrade Your Mezzanine Flooring While Avoiding Timely and Costly Replacement

DEC

5

2023

MATERIAL HANDLING, SHELVING

Comparing Shelving Systems for Industrial Pallet Racks: How to Pick the Best Solution

APR

25

2023

MATERIAL HANDLING, ROBOTICS, SELF-STORAGE

Warehouse Expansion: What To Consider When It's Time to Expand

AUG

23

2022

MATERIAL HANDLING, ROBOTICS, SELF-STORAGE

ResinDek Products Receive Renewed SCS Certification of Environmental Sustainability

JUL

7

2022

MATERIAL HANDLING, ROBOTICS, SELF-STORAGE

Key Flooring Considerations When Updating an Existing Industrial Mezzanine System

MAR

1

2022

ROBOTICS AGVs AND AMRs

6 Ways Engineered Mezzanine Flooring Maximizes Implementation Success

SEP

14

2021

MATERIAL HANDLING, ROBOTICS, SELF-STORAGE

Three Reasons Why Your Industrial Mezzanine Floors Should Have IAPMO Validation

AUG

31

2021

MATERIAL HANDLING, ROBOTICS, SELF-STORAGE

How Warehouse Mezzanine Flooring Earns Credits for LEED® Certification

JUN

29

2021

MATERIAL HANDLING, ROBOTICS, SELF-STORAGE

Mezzanine Floors: Strong, Sustainable, Speedy, Safe, Spacious

JAN

24

2021

MATERIAL HANDLING, ROBOTICS, SELF-STORAGE

Study Finds ResinDek® Flooring 34% More Cost Effective Than Concrete

MAY

31

2019

MATERIAL HANDLING, ROBOTICS, SELF-STORAGE

New ResinDek with MetaGard® Finish: Our Strongest Surface Option Yet

MAY

21

2018

MATERIAL HANDLING, ROBOTICS, SELF-STORAGE

The Ergonomic Dangers of Concrete Flooring (And How ResinDek® Floors Can Help)