METAGARD® SST

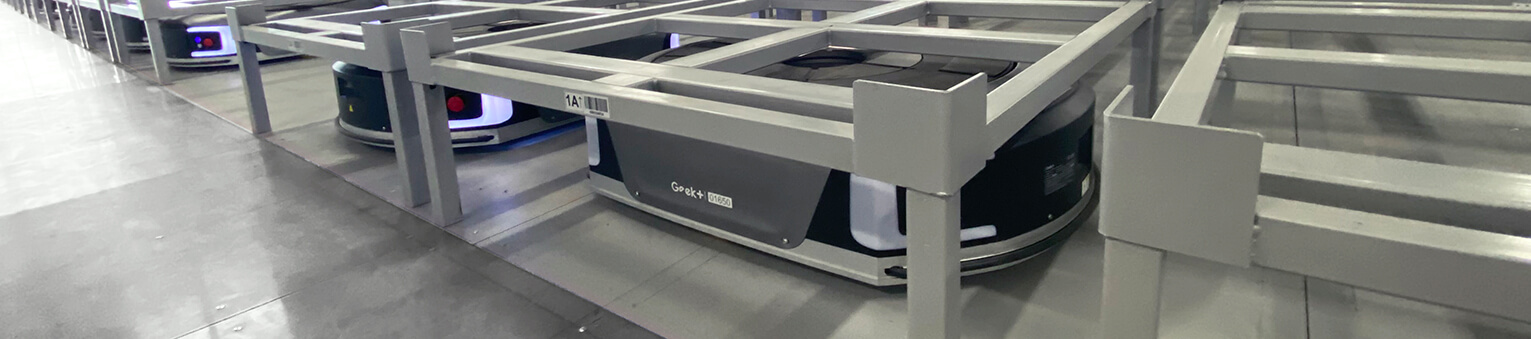

STAINLESS STEEL FLOORING PANELS ENGINEERED FOR EXCEPTIONAL DURUABILTY WITH AMR AND AGV TRAFFIC

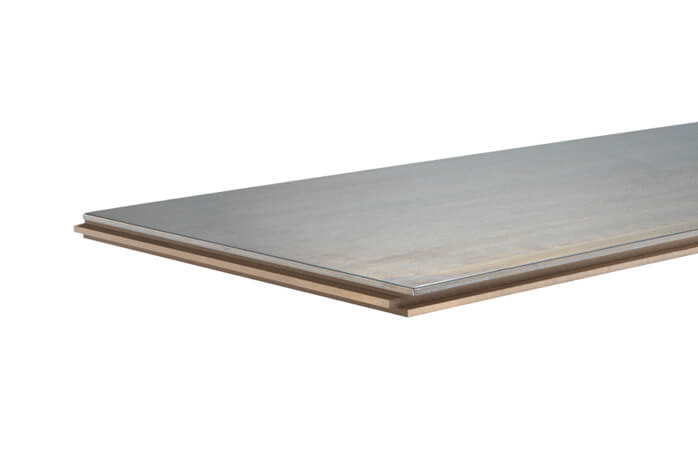

Designed for the extreme wear of heavy automatic guided vehicles (AGVs) and their loads, MetaGard® SST steel decking is Cornerstone’s most durable finish offering. It consists of stainless steel that encapsulates the top and sides of a ResinDek® engineered wood flooring panel. This allows MetaGard SST to provide ironclad resistance to wear, gouges, scratches, and other damage in abusive, harsh environments.

In testing, ResinDek with MegaGard SST has shown 5x more abrasion resistance than concrete in heavily trafficked areas where dirt and debris are not routinely removed. This includes 24/7 operations that restrict or prohibit employee access. ResinDek with MetaGard SST has also been proven to withstand more than 2 million annual pivoting passes generated when AGVs change direction.

The steel is fused to the ResinDek flooring panel with a proprietary bonding agent. This creates a floor that will not delaminate while offering superior physical properties. Perfectly level to accommodate robotic vehicle travel, the encapsulation process eliminates sharp edges to ensure that AGV wheels passing over the flooring surface are not cut or snagged.

Engineered to ensure a smooth panel-to-panel transition, ResinDek with MetaGard SST panels can be used alongside other ResinDek panels without a steel surface, such as those coated with TriGard® ESD. This coating incorporates an electrostatic dissipative (ESD) material that complies with ANSI/ESD Association specifications to protect sensitive, on-board electronic equipment from damage.

COMBINE RESINDEK WITH METAGARD SST AND TRIGARD ESD FOR A ROBOTIC COST-EFFECTIVE FLOORING SOLUTION

Combining flooring panels with the two finishes in an installation (ResinDek with MetaGard in the higher traffic, debris-laden areas and ResinDek with TriGard ESD in the cleaner, lower traffic regions) is recommended. This creates a more cost-effective solution by using MetaGard SST flooring only in the areas of maximum wear.

MetaGard SST has been tested in accordance with the following standards:

Dynamic Coefficient of Friction: ASTM A326.3

Test Procedure: Neolite sensor has material that is 95+/-3 Shore A

Results: Average Dry: 0.77 | Average Wet: 0.68

Wear Resistance: ASTM D4060 Taber Abrasion

Test Procedure: Grit aluminum oxide sandpaper replaced every 500 cycles with 1 kg of weight

Results: Wear Rating: >50,000 cycles

Gouge Resistance: ASTM D2197

Test Procedure: Tested with weights ranging from 1kg to 10.5kgs

Results: No Failure

Light Reflectivity: ASTM D523 Gloss, 85 Deg

Test Procedure: Tested with glossmeter geometries of 85°

Results: 8 GRUs

RELATED DOCUMENTS

RELATED VIDEOS

Why Choose ResinDek with MetaGard? | Video Length: 0:34

Elevated Flooring Solutions for AGVs and AMRs | Video Length: 2:54