AGV & AMR Robotic Manufacturers

Maximize Throughput, Choose a Flooring Manufacturer that Works with Robotic Manufacturers

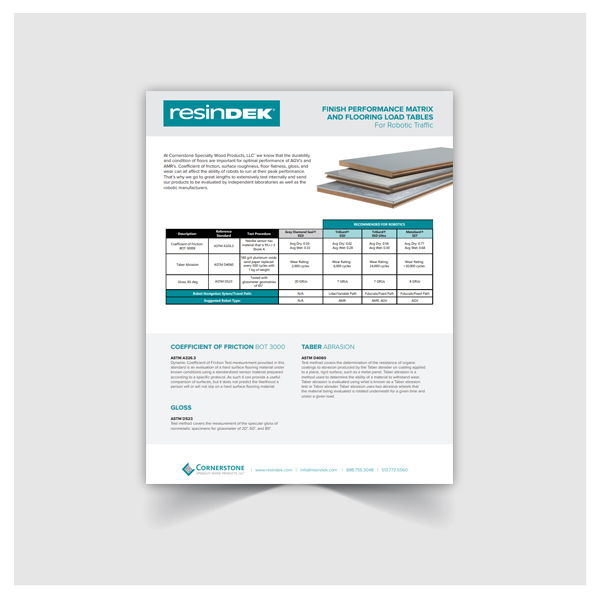

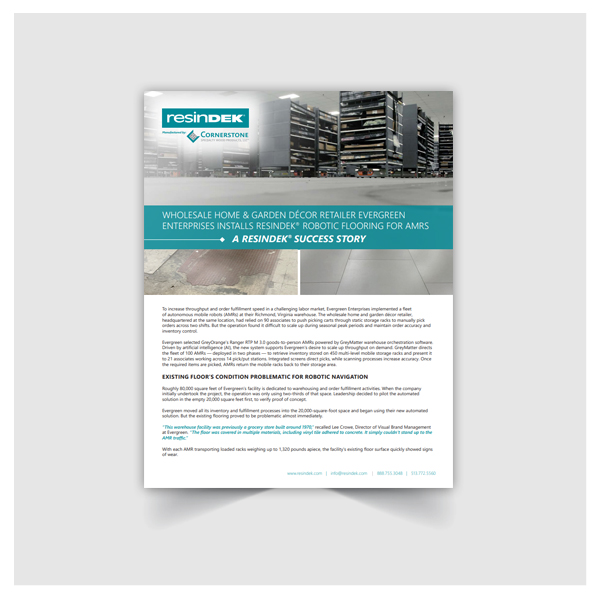

With more operations implementing robotic solutions such as autonomous mobile robots (AMRs) and automatic guided vehicles (AGVs) to increase throughput and operational efficiency, it’s important to create an environment that maximizes the productivity of these technologies. Coefficient of friction, surface roughness, floor flatness, gloss, and wear can all affect the ability of AGVs and AMRs to run at their peak level. Therefore, it is important that testing and evaluation happen upfront, and that AGV and AMR Manufactures are involved in the flooring selection process.

ResinDek Industrial Flooring for Robotic Operations

- ResinDek flooring is specifically engineered to meet the needs of robotic traffic

- ResinDek engineered wood panels have been extensively tested with AGVs and AMRs for the coefficient of friction, surface roughness, wear resistant, and light reflectivity

- We partner with AGV and AMR manufacturers to provide flooring products for their testing labs

- Millions of square feet of ResinDek panels currently supporting robotic traffic in distribution centers, warehouses, retail stores, and micro fulfillment centers worldwide

ResinDek® AGV and AMR Flooring Panels

ResinDek composite engineered flooring panels have the proven structural integrity to support dynamic and static pallet jack load limits from 2,000 – 8,000 lbs (910 – 3360 kg) and the rigorous demands of robotic traffic such as AGVs and AMRs.

We recommend that a minimum of 20-gauge (0.9 mm) corrugated metal B Deck be used on all ResinDek flooring projects (except for Xspan®) and a minimum of 18 gauge (1.2 mm) when live and dead loads exceed 2,500 Ibs. (1135 kg) ResinDek Xspan and Xspan FR do not require a corrugated metal deck. ResinDek flooring panels LD, MD and HD are ¾” (19 mm) thick, ResinDek Max is 1-1/2″ (38 mm) thick, and ResinDek Xspan and Xspan FR are 1-1/8″ (28mm) thick.

For Use with Corrugated B-Deck:

ResinDek LD

3/4″ (19mm) Thick Panel

Robot Loads up to:

500 lbs/230 kg

Pallet Loads up to:

2,000 lbs/910 kg

ResinDek LD

ResinDek MD

3/4″ (19mm) Thick Panel

Robot Loads up to:

2,000 lbs/910 kg

Pallet Loads up to:

3,500 lbs/1,590 kg

ResinDek MD

ResinDek HD

3/4″ (19mm) Thick Panel

Robot Loads up to:

4,000 lbs/1,815 kg

Pallet Loads up to:

4,500 lbs/2,045 kg

ResinDek HD

ResinDek WR

3/4″ (19mm) Thick Panel

Robot Loads up to:

500 lbs/230 kg

Pallet Loads up to:

2,000 lbs/910 kg

ResinDek WR

ResinDek MAX

1-1/2” (38mm)Thick Panel

Robot Loads up to:

6,000 lbs/2,275 kg

Pallet Loads up to:

8,000 lbs/3,360 kg

ResinDek MAX

No Corrugated B-Deck Required (Single Panel Solution):

ResinDek HD

3/4″ (19mm) Thick Panel

Robot Loads up to:

4,000 lbs/1,815 kg

Pallet Loads up to:

4,500 lbs/2,045 kg

ResinDek HD

ResinDek Xspan / Xspan FR

1-1/8” (28mm) Thick Panel

Robot Loads up to:

2,500 lbs/1,135 kg

Pallet Loads up to:

3,000 lbs/1,365 kg

ResinDek Xspan & FR

For Use with a Sub Floor:

ResinDek ReShield

¼” (6mm) Thick Panel

Robot Loads up to:

3,000 lbs /1,365 kg

Pallet Loads up to:

3,500 lbs /1,590 kg

ResinDek ReShield

Locus Robotics

Locus Robotics is a global leader of autonomous mobile robots. Steve Simmerman, Head of Global Alliances and Steve Branch, Senior Director, Sales Engineering talk about their partnership with Cornerstone Specialty Wood Products and all of the benefits that ResinDek flooring provides for their customers’ mezzanine solutions.