RESINDEK® MAX

INDUSTRIAL WORK PLATFORM ENGINEERED FOR ROLLING ELECTRIC PALLET JACK LOADS AND MOBILE ROBOTS

ResinDek MAX can easily handle the daily rigors of electric pallet jack rolling loads in distribution centers, warehouses, and manufacturing facilities. Each ResinDek panel is precision engineered with a tongue-and-groove configuration promoting effective panel to panel wheel load transfer. When required, tongue-and-groove configurations are available on all 4 sides.

Panel Thickness:1-1/2"

Panel Weight:7.6 psf

Pallet Jack & Product Load Limits:pallet jack rolling loads

up to 8,000 lbs with 18 GA B-Deck

Mobile Robot & Product Load Limits:AGV/AMR rolling loads

up to 6,000 lbs with 18 GA B-Deck

* Reference the Load Span Tables below for Allowable Uniform & Total Product Loads.

* See Full Product Comparison Chart here.

PRODUCT DESCRIPTION

This extreme maximum duty mezzanine flooring is manufactured with specially sorted and processed wood fibers, customized formaldehyde free resins, a wax emulsifier for moisture resistance, and then compressed under extremely high pressure and temperature. The result is an industrial composite wood flooring panel that has superior physical properties ensuring that your floor will be a showcase year after year.

ResinDek MAX panels are custom manufactured and available in sizes up to 4' x 10' (1219 mm x 3048 mm) with our proprietary coatings and up to 4' x 8' (1219 mm x 2438 mm) with our MetaGard® steel surface for extreme wear conditions such aggressive dragging or pulling skids. A minimum of 18-gauge corrugated metal B deck is required for loads exceeding 2,500 lbs.

We offer everything you will need to incorporate ResinDek MAX floor panels into your facility, from our ResinDek fastening systems to corrugated metal decking. Learn why ResinDek MAX was chosen for a large grocery store's cold storage warehouse floor by reading this success story.

RESINDEK MAX FOR AGVS, AMRS, HEAVY EQUIPMENT, ROLLING LOADS & PALLET JACKS – For use with Corrugated B-Deck

| Product Name (B Deck Gauge) | Pallet Jack & Product Load Limits | Robot & Product Load Limits | Maximum Robot Contact Pressure |

|---|---|---|---|

| ResinDek® MAX (18ga) | up to 8,000 lbs. | up to 6,000 lbs. | 1,500 psi |

NOTES FOR TABLES ABOVE:

- Testing was completed with polyurethane caster wheels and any deviation or alternative wheels such as crowned, steel or plastic could void the warranty. Contact CSWP for more information.

- Contact pressure values are to be used as a guide. Please consult factory for specific robot usage.

- For flooring solutions with B-Deck: Load values above are calculated on 36" beam spacing, increased spacing will reduce capacity. Floor Deflection is L/240.

OPTIONAL FINISHES

FOR HEAVY EQUIPMENT, STORAGE, ROLLING CARTS & PALLET JACKS

Gray Diamond Seal® Coating

Gray Diamond Seal® ESD Coating

MetaGard® Steel Decking Surface - GVT

Unfinished

FOR AGV & AMR ROBOTIC TRAFFIC

INDUSTRIAL MEZZANINE DECKING FASTENING SYSTEMS

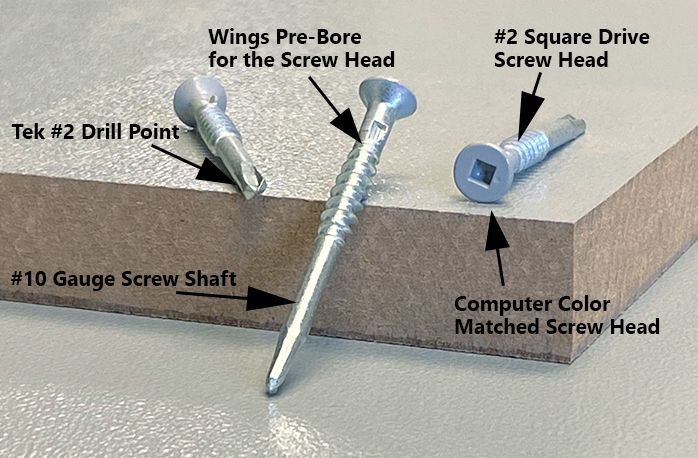

TOP SIDE ENGINEERED FASTENERS

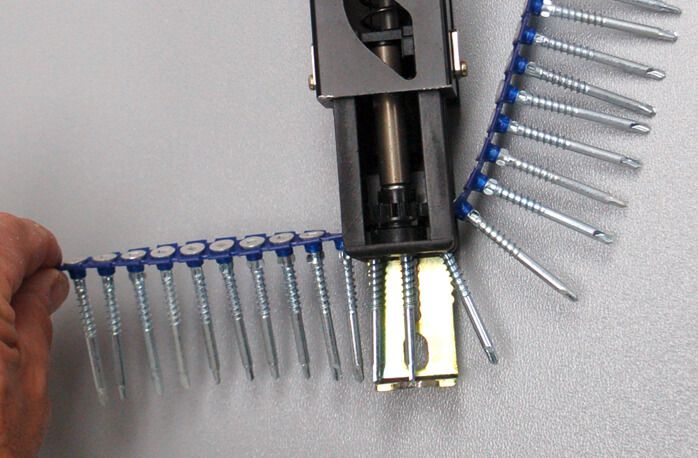

For conventional top side fastener installation, use Cornerstone Specialty Wood Products, LLC® Collated Stand-up Screwdriver and collated engineered drill screws. Not only will the collated screwdriver gun save you up to 40% in fastening costs, but it will reduce installation fatigue with its ergonomic design.

The top side engineered fasteners are designed for strength, durability and easy installation. No countersinking or pre-drilling is required as the wings are near the top of the shaft, which counterbore for screwheads. The number 2 square drive heads and points easily pierce up to 12 gauge steel decking and is designed to drill through wood and steel decking prior to the threads engaging, thus preventing the mezzanine floor panels from lifting.

In addition, our engineered fasteners offer the following advantages:

- More consistent screw depth with greater control and settings

- Easy to load screw tips

- Fast and easy bit tip replacements

- Requires minimal training

- Stout #10 wire gauge screw

- Zinc coating for high humidity environments resists corrosion

- Your choice of gray or beige engineered fasteners

INVISI-LOC® UNDERSIDE ENGINEERED FASTENING SYSTEM

Invisi-Loc provides showcase mezzanine floors with no visible fasteners that are dependable, economical and easy to install. The Invisi-Loc under deck engineered fastening system mounts fasteners under the mezzanine decking hiding unwanted screw holes on top. Plus, when installed with our pre-punched corrugated metal decking, installation time is reduced and potentially dangerous metal shavings are eliminated.

- 20 Invisi-Loc engineered fasteners are required per 4' x 8' sheet. A pneudralic installation tool and a standard medium duty air compressor supplies the required power.

- Corrugated metal decking is pre-punched and B metal deck is fastened to the bar joists like other steel decking using drilling screws or welding.

- All pneudralic installation tools can be rented or purchased from Cornerstone Specialty Wood Products, LLC.

- When installed according to Cornerstone Specialty Wood Products, LLC specifications the Invisi-Loc® Underside Engineered Fastening System carries a 10-year warranty.

COLLATED SCREWS FOR CORRUGATED METAL DECK

B-Deck screws work best in roll form beams and structural steel under 3/16" thick. Valleys less than 2-1/2" wide may not accommodate the screwdriver. Contact Cornerstone Specialty Wood Products, LLC for additional information.

Note: Additional Fastening Systems are available, please contact Cornerstone Specialty Wood Products, LLC® for more information.