Self-Storage Facilities

Save Construction Time & Money by Using ResinDek® Flooring

ResinDek® flooring panels, manufactured by Cornerstone Specialty Wood Products, LLC® provide a tremendous value for elevated floors in self-storage buildings. ResinDek composite engineered wood flooring panels are extremely durable, provide a showcase appearance and are easy to maintain. They have the proven structural integrity and the strength you associate with a concrete floor yet can offer savings of tens of thousands of dollars. ResinDek panels offer a compelling value for both new construction and retrofitting existing facilities and is backed by a 10-year product warranty.

How can you realize savings of up to $5/sqft by using ResinDek instead of concrete and get a product that is backed by a 10-year warranty?

- ResinDek is at least 40 lbs per square foot (18 kg per square meter) lighter than concrete which allows for less steel to be used in the support structure, along with potential savings in the foundation and footers.

- ResinDek is supplied with a factory finish so tracks can be laid for the storage units immediately after the flooring is installed. Concrete typically needs a week or more to cure before tapcons can be used to continue construction.

- ResinDek has an allowable deflection of L/240 whereas concrete’s allowable deflection is L/360. This creates a more ergonomic platform and again allows for less steel in the support structure.

- Material cost per square foot is less than that of concrete.

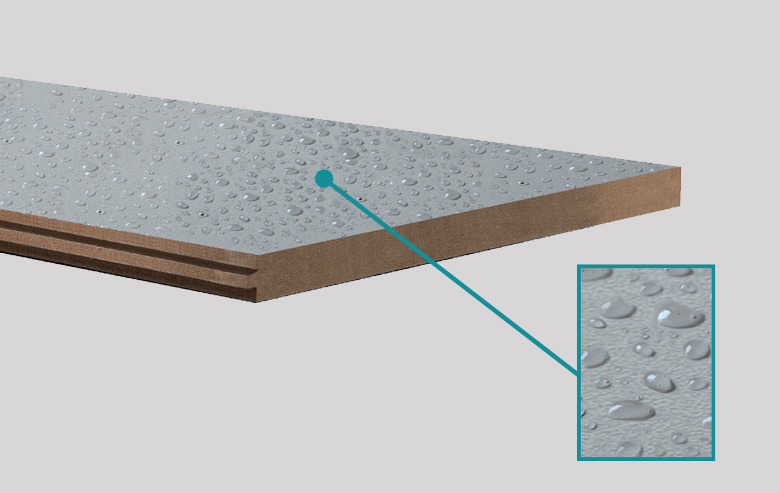

ResinDek® WR Water Resistant Flooring Panel

ResinDek WR flooring panels are perfect for self-storage facilities, modular offices, or any new construction project exposed to outdoor elements for up to 120 days. Their exceptional moisture resistance, meeting the stringent MR90 standard, ensures long-lasting durability, even in challenging environments – including interior applications with high humidity and limited washdown applications. ResinDek WR panels can be used on both the ground floor as well as mezzanine applications.

Resindek® Floor Panels for Self-Storage Facilities

ResinDek composite engineered flooring panels have the proven structural integrity to support dynamic and static pallet jack load limits from 2,000 – 8,000 lbs (910 – 3360 kg) and the rigorous demands of robotic traffic such as AGVs and AMRs.

We recommend that a minimum of 20-gauge (0.9 mm) corrugated metal B Deck be used on all ResinDek flooring projects (except for Xspan®) and a minimum of 18 gauge (1.2 mm) when live and dead loads exceed 2,500 Ibs. (1135 kg) ResinDek Xspan and Xspan FR do not require a corrugated metal deck. ResinDek flooring panels LD, MD and HD are ¾” (19 mm) thick, ResinDek Max is 1-1/2″ (38 mm) thick, and ResinDek Xspan and Xspan FR are 1-1/8″ (28mm) thick.

For Use with Corrugated B-Deck:

ResinDek LD

3/4″ (19mm) Thick Panel

Robot Loads up to:

500 lbs/230 kg

Pallet Loads up to:

2,000 lbs/910 kg

ResinDek LD

ResinDek MD

3/4″ (19mm) Thick Panel

Robot Loads up to:

2,000 lbs/910 kg

Pallet Loads up to:

3,500 lbs/1,590 kg

ResinDek MD

ResinDek HD

3/4″ (19mm) Thick Panel

Robot Loads up to:

4,000 lbs/1,815 kg

Pallet Loads up to:

4,500 lbs/2,045 kg

ResinDek HD

ResinDek WR

3/4″ (19mm) Thick Panel

Robot Loads up to:

500 lbs/230 kg

Pallet Loads up to:

2,000 lbs/910 kg

ResinDek WR

ResinDek MAX

1-1/2” (38mm)Thick Panel

Robot Loads up to:

6,000 lbs/2,275 kg

Pallet Loads up to:

8,000 lbs/3,360 kg

ResinDek MAX

No Corrugated B-Deck Required (Single Panel Solution):

ResinDek HD

3/4″ (19mm) Thick Panel

Robot Loads up to:

4,000 lbs/1,815 kg

Pallet Loads up to:

4,500 lbs/2,045 kg

ResinDek HD

ResinDek Xspan / Xspan FR

1-1/8” (28mm) Thick Panel

Robot Loads up to:

2,500 lbs/1,135 kg

Pallet Loads up to:

3,000 lbs/1,365 kg

ResinDek Xspan & FR

For Use with a Sub Floor:

ResinDek ReShield

¼” (6mm) Thick Panel

Robot Loads up to:

3,000 lbs /1,365 kg

Pallet Loads up to:

3,500 lbs /1,590 kg

ResinDek ReShield

Optional Coatings & Finishes

For Heavy Equipment, Storage, Rolling Carts & Pallet Jacks

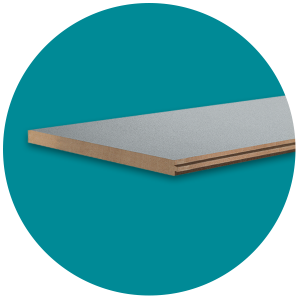

Gray Diamond Seal® Coating

Gray Diamond Seal®

ESD Coating

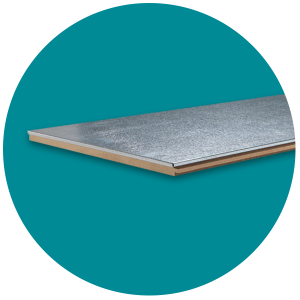

MetaGard® GVT Steel Decking Surface

Unfinished

For AGV & AMR Robotic Traffic

TriGard®

ESD Ultra Coating

TriGard®

ESD Coating

MetaGard® SST Steel Decking Surface

The Flooring Solution for Self-Storage Facilities

ResinDek provides not only a significant cost savings compared to concrete, but also allows for a quick installation. Learn about the benefits of ResinDek for Self-Storage.